Incorporating Microchannel Technology into Modular HVAC Systems

Modular HVAC systems are gaining traction across commercial and industrial markets due to their flexibility, scalability, and ease of installation. Pre-engineered units offer instant deployment and easy maintenance—ideal for applications ranging from data centers to hospitals and multi-tenant properties. As demand for more compact, energy-efficient solutions rises, microchannel heat exchangers lead the way in enabling the next generation of modular system design.

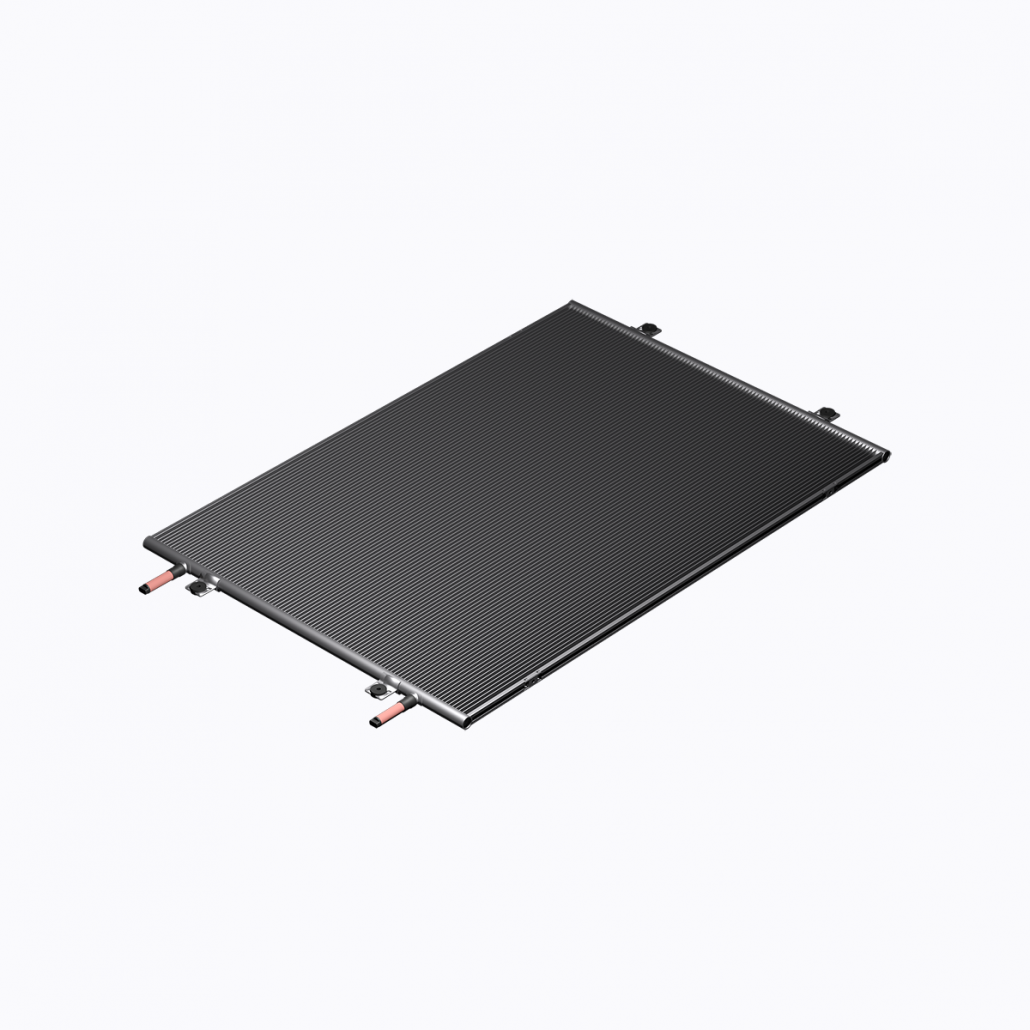

Compact Design Supports Space-Efficient Integration

One of the best reasons to use microchannel technology on modular HVAC applications is its built-in small size. Compared to standard copper-aluminum coils that are larger and heavier, microchannel heat exchangers consist of flat aluminum tubing with multiple internal flow passages. This topology enables maximum thermal transfer and occupies less space—critical when designing modular units that must be fitted into constricted mechanical rooms or rooftop spaces.

The reduced footprint of microchannel coils also makes it possible for more flexible layout within modular systems like here. Components can be built with greater airflow routes, less refrigerant circuitry, and better component location without compromising overall dimensions. Such integration promotes both performance and service ease, and modular systems realize improved versatility within a wide range of installation conditions.

Also, the lower weight of microchannel components …

Continue Reading